English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski

Products

- Tape machine

- Sponge strip paste machine

- Cosmetic labeling machine

- Sleeve labeling machine

- Roll film labeling machine

- Assembly line labeling machine

- Right Angle Labeling Machine

- Automatic labeling machine

- Automatic multifunctional labeling machine

- Semi - automatic multifunctional labeling machine

- Semi - automatic round bottle labeling machine

- Semi - automatic flat labeling machine

- Automatic horizontal labeling machine

- Automatic round bottle labeling machine

- Automatic paging labeling machine

- Automatic side plane labeling machine

- Automatic flat labeling machine

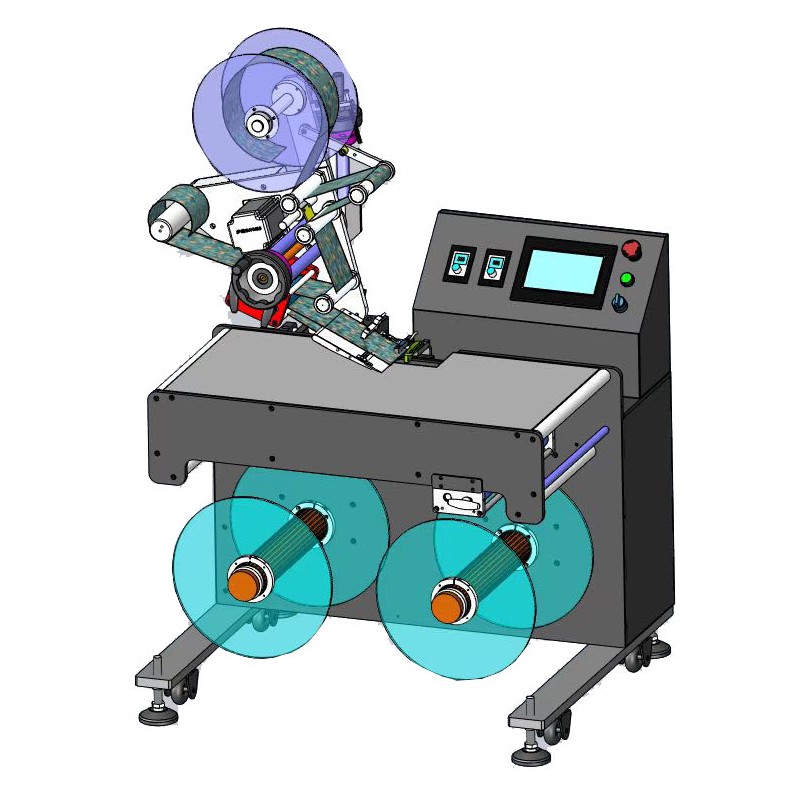

Custom rewind machine

This Custom rewind machine is available in intermittent and continuous modes, with manual switching. It typically operates in intermittent mode when paired with laser marking machines, while continuous mode is preferred for inkjet coding systems.

Suitable for rewinding or winding of ring materials, such as electronic tags, adhesive labels, 3M labels, bar code labels, roll film, fabric, tourniquets, medical supplies, etc., widely used in the electronic industry, medical and printing industry of roll materials.

Suitable for rewinding or winding of ring materials, such as electronic tags, adhesive labels, 3M labels, bar code labels, roll film, fabric, tourniquets, medical supplies, etc., widely used in the electronic industry, medical and printing industry of roll materials.

Send Inquiry

Product Description

Extensive application: Custom rewind machine is suitable for rewinding standard tapes with base film widths ranging from 20 to 200 mm.

Durable and strong: the motherboard is made of national standard 6061 aluminum plate, the chassis is made of stainless steel, and the key components should be rigidly connected to ensure the rigidity and stability of the connection parts.

A high-performance electrical control system featuring PLC, touch screen, HD precision measurement tags, and an integrated vision system, ensuring exceptional stability.

Simple adjustment, the design freedom can be adjusted, the conversion between different products is simple and time-saving;

The touch screen interface features bilingual annotations and comprehensive fault diagnosis prompts, with intuitive parameter adjustments for effortless operation.

Powerful, with production counting function, power saving function, production number setting prompt function, parameter setting protection function, convenient production management;

◆ Optional features and components: ① Thermal coding/spray coding; ② Laser marking; ③ Additional functions (customized according to customer requirements).

Durable and strong: the motherboard is made of national standard 6061 aluminum plate, the chassis is made of stainless steel, and the key components should be rigidly connected to ensure the rigidity and stability of the connection parts.

A high-performance electrical control system featuring PLC, touch screen, HD precision measurement tags, and an integrated vision system, ensuring exceptional stability.

Simple adjustment, the design freedom can be adjusted, the conversion between different products is simple and time-saving;

The touch screen interface features bilingual annotations and comprehensive fault diagnosis prompts, with intuitive parameter adjustments for effortless operation.

Powerful, with production counting function, power saving function, production number setting prompt function, parameter setting protection function, convenient production management;

◆ Optional features and components: ① Thermal coding/spray coding; ② Laser marking; ③ Additional functions (customized according to customer requirements).

Technical Parameters

* Volume label speed: 0 to 50 meters per minute (adjustable as needed)

* Coil size: inner hole 76mm, outer diameter 300mm;

*Applicable label size: width 10mm~150mm,

*Overall dimensions: 700mm×480mm×600mm (length×width×height);

* Applicable power supply: 200V 50/60Hz;

* Weight: 50kg;

*Total power: 450W

* Coil size: inner hole 76mm, outer diameter 300mm;

*Applicable label size: width 10mm~150mm,

*Overall dimensions: 700mm×480mm×600mm (length×width×height);

* Applicable power supply: 200V 50/60Hz;

* Weight: 50kg;

*Total power: 450W

Configuration details and parameters:

| Main organization configuration | Organization name | quantity | Main materials | Organization name | quantity | Main materials |

| Unroll mechanism | 1 set | Stainless steel, aluminum alloy | Guide drum | 1 set | alufer | |

| haulage gear | 1 set | Aluminum alloy, steel, rubber coated roller | Scroller | 1 set | Stainless steel, aluminum alloy | |

| electricity box | 1 set | stainless steel | Hand Swell | 2 sets | self-control | |

| Main electrical configuration | Electrical name | quantity | ts | Electrical name | quantity | ts |

| touch screen +PLC | 1 set | YUNCON/colmay | pulling motor | 1 set | HongSEN | |

| Switching Mode Power Supply | 1 set | Mingwei | Traction Motor Driver | 1 set | HongSEN | |

| ring transformer | 1 set | domestic | magnetic particle | 2 sets | domestic | |

| Planetary reducer | 1 set | domestic | controller | 2 sets | domestic | |

| Unroll speed | 0 to 50 meters per minute | |||||

| Applicable material width | The label backing paper width is 150mm or less | |||||

| Applicable material size | The material tray has a diameter of 300mm, with a 76mm inner hole for the coil core. | |||||

| Optional features | Laser machines, inkjet coding machines, and ribbon coding machines all have signal sources that can be connected. | |||||

| voltage | 220V | |||||

| Machine size: | L700mm×W480mm×H600mm | |||||

Note: The configuration may be adjusted reasonably based on the actual material delivery schedule under the same configuration, and the configuration may be revised according to customer requirements.

Hot Tags: Custom rewind machine, China, Factory, Manufacturers, Suppliers, Price, Made in China

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy